Advanced Manufacturing

Powering the Future of Manufacturing

Transform your operations with cutting-edge technology, process optimization, and expert guidance.

95%

Of manufacturers are using or evaluating smart manufacturing technology, up from 81% in 2023.

38%

Manufacturers with annual revenues of less than $500 million use only 38% of their data effectively.

541,302

New robots were added for manufacturing in 2023, the third straight year with more than 500,000 robots deployed.

Innovate, Automate,

and Elevate Your Manufacturing

We help manufacturers integrate advanced manufacturing solutions that improve efficiency, reduce costs, and drive innovation. Whether you’re looking to adopt automation, enhance quality control, or implement technology adoption, our expert team is here to support you every step of the way.

Advanced Manufacturing Services

Key Benefits

Increased Productivity:

Automation and process improvements drive faster production cycles.

Cost

Savings:

Reduce material waste and operational inefficiencies.

Enhanced Quality Control:

Ensure precision and consistency in manufacturing.

Future-Proofing:

Stay ahead with the latest manufacturing technologies.

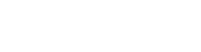

Case Study: AMG Industries

Challenge: AMG needed to improve productivity on a repetitive, labor-intensive part but wasn’t ready to invest in automation without proof it would work.

Solution: Through our Collaborative Robot Loan Program, engineers helped test, program, and deploy a UR robot on-site.

Result: Productivity increased by 38%, ROI was achieved in just 6.5 months, and AMG purchased their own robot—now exploring further automation across operations.

The robot loan program helped us prove the concept, increase productivity by 38%, and achieve ROI in just over 6 months. We’ve already purchased our own and are planning to automate more.”

— Jes Salmons, Director of Engineering, AMG

Elevate Your Manufacturing Operations

Ready to integrate advanced technologies and optimize your manufacturing processes? Contact us today to get started.